Advantages of the PB3D System Construction Method

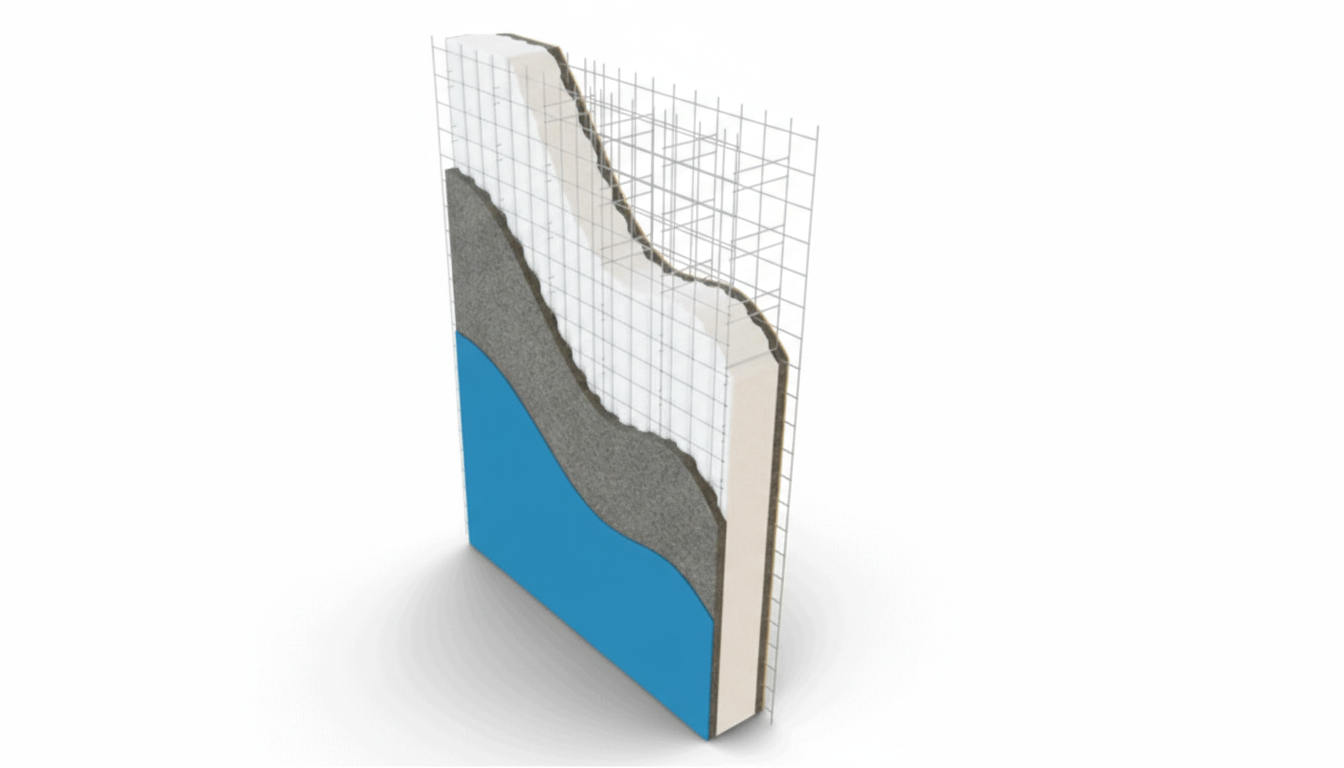

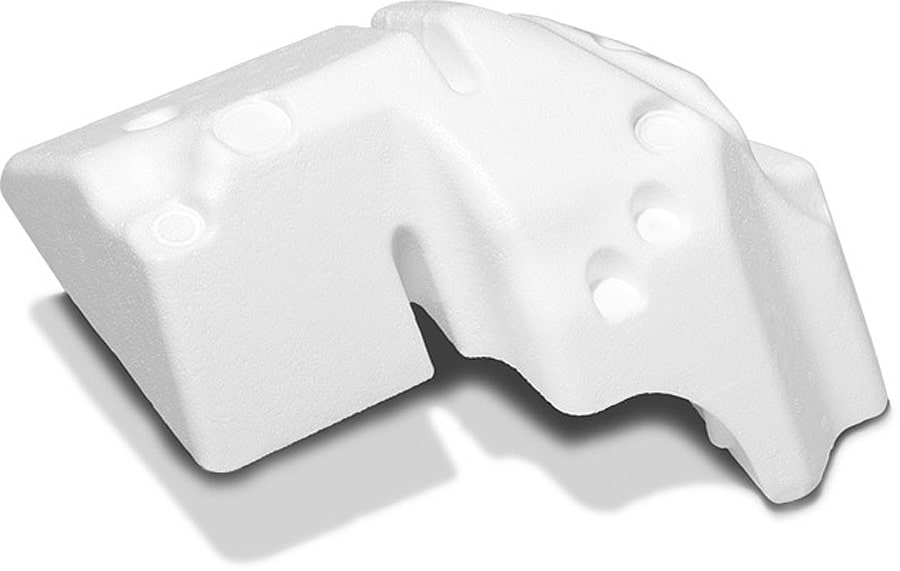

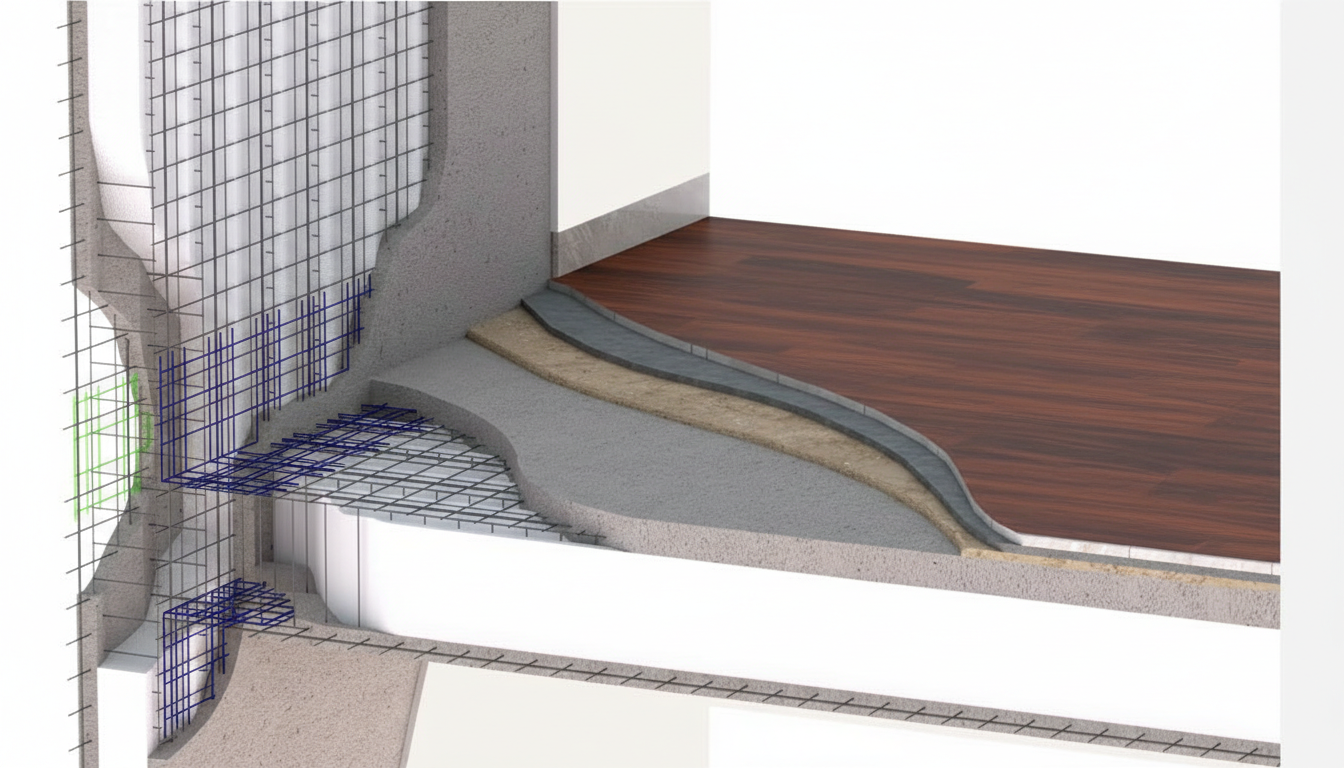

The PB3D System is a next-generation industrialized construction system based on rigid EPS (Expanded Polystyrene) panels reinforced with welded steel mesh, designed to meet today’s demands for structural efficiency, fast execution, sustainability, and indoor comfort.

Its technology is derived from widely proven systems, with specific adaptations that optimize performance across different construction contexts.